RINOL COATING SYSTEMS FOR

CONDUCTIVE FLOORS

SAFETY, HYGIENE AND CONDUCTIVITY TO GUARANTEE

SPECIAL REQUIREMENTS

In addition to the “normal” loads, special requirements are also placed on coating systems depending on the area of application. These include a wide variety of production areas in the electrical and automotive industries, hospitals and operating theatres as well as explosion-proof rooms.

Charging can occur, for example, through walking or driving on coating systems. But positive and negative charges are also generated by contact or friction. Undefined discharges can damage sensitive assemblies and also endanger the people working there.

We have our special casting resin systems for these particular areas. Each of these systems offers a hard-wearing, non-porous and seamless surface. Optionally, they can be designed with a slip-resistant surface.

The special RINOL coating systems are tested for their safety by renowned, independent experts and accredited institutes.

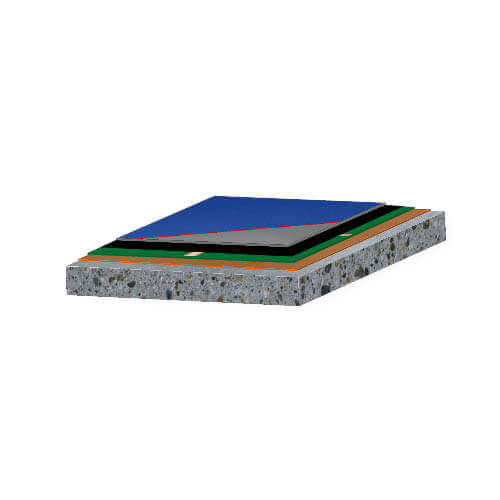

RINOLETEC

The electrically conductive coating system is tested according to DIN EN 61340-4-1, 61340-4-5 and 61340-5-1. RINOLETEC is applied in three layers. Optionally, a levelling layer and a coloured sealant can be applied in addition. The surface is smooth and easy to clean.

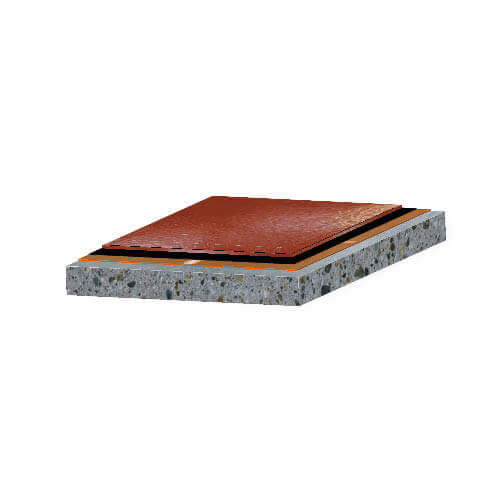

RINOLETEC THIXO

The electrically conductive sealing system is tested according to DIN EN 61340-4-1, 61340-4-5 and 61340-5-1. RINOLETEC THIXO is an economical surface protection with a dimpled structure. The dust-binding, hard-wearing sealing system can be applied to the existing floor without joints.

RINOLQCR AST

The electrically conductive coating system is tested according to DIN EN 61340-4-1, 61340-4-5 and 61340-5-1. RINOLQCR AST is based on high-quality epoxy resins and is applied in several layers. The slip-resistant surface has very good chemical resistance.